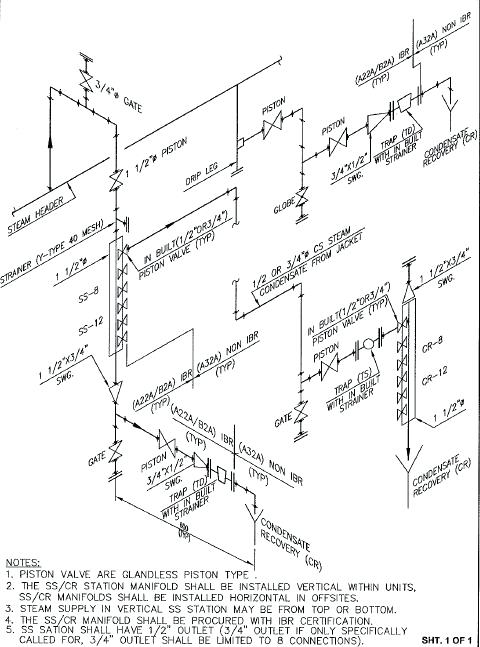

The direction of flow is indicated by an arrowhead at the end of the line where it meets the next component as well as at every 90 degree turn. Typically all pipes will run either vertically or horizontally and use only right angles. These examples use single solid lines which represent simple rigid pipes or tubing.

Various types of lines are used to represent different pipes, tubes, and hoses. The pipe lines are represented by lines connecting to each side of the valve symbol. The generic symbol for a 2-way valve is two triangles pointing to each other with the tips of the inner points touching. The purpose is NOT to serve as a floor plan or map of the system, it is to illustrate the process of the system. Another important consideration is that the diagrams do NOT always represent the physical locations and proximity of each component. These symbols are also labeled with words, letters, and numbers to further identify and specify the components that they are representing. They are merely used to represent a certain type of component. It is important to note that these symbols are NOT to scale and are NOT dimensionally accurate. There are standard symbols used to represent the components in these diagrams. P&IDs also are used as the basis for the live graphic representation of a process system in its HMI (human-machine interface) or other control system. Maintenance and modification to the system.

Employee training of process system operation.Startup, shutdown, and operating schemes and procedures.Installation and/or build-out of the system.

Safety and operational analysis (HAZOP – hazard and operability study).As such, the P&ID is crucial in all stages of process system development and operation. The P&ID is the primary schematic drawing used for laying out a process control system’s installation. A piping and instrumentation diagram (P&ID) is a graphic representation of a process system that includes the piping, vessels, control valves, instrumentation, and other process components and equipment in the system.

0 kommentar(er)

0 kommentar(er)